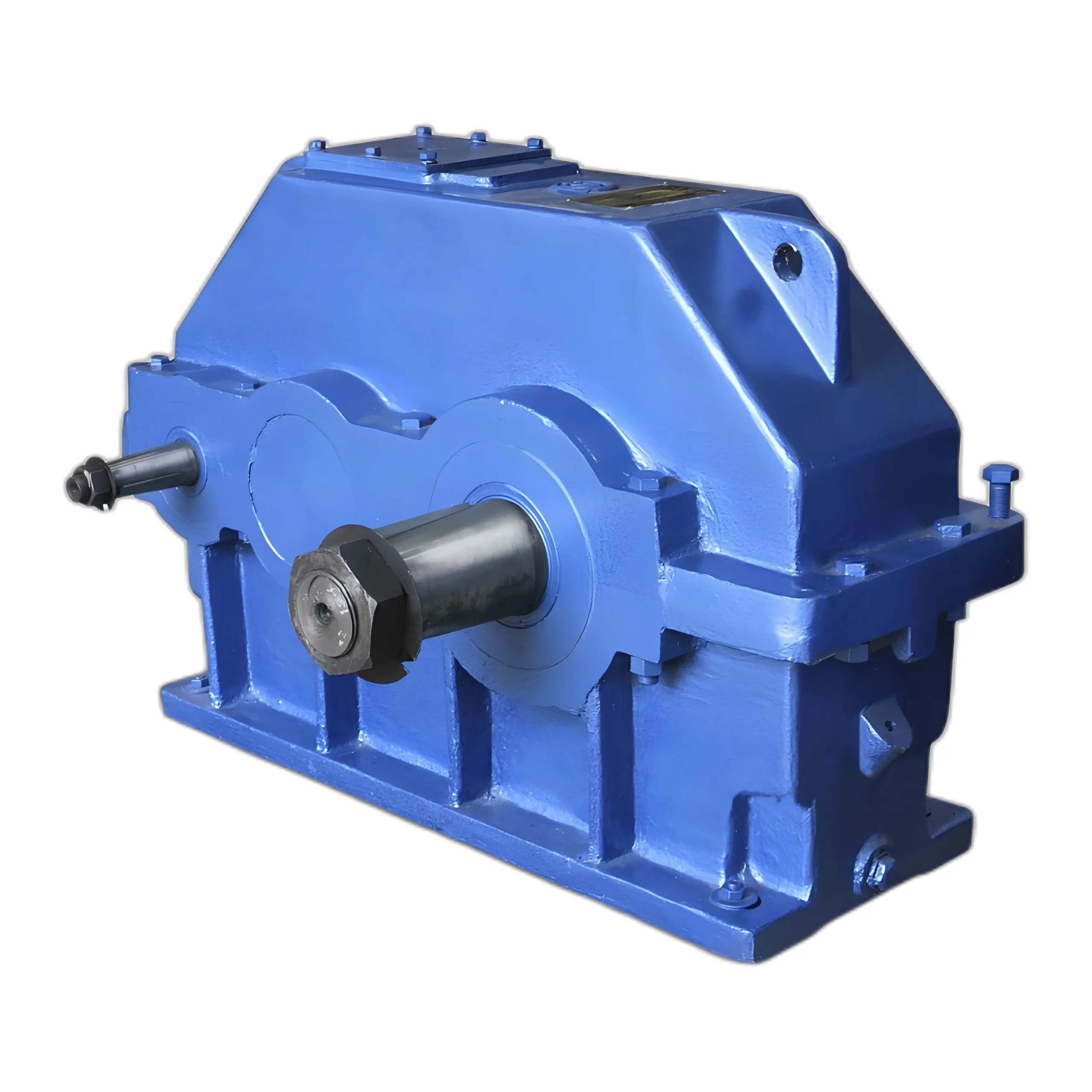

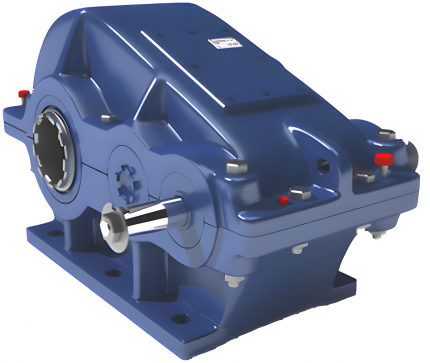

Main » Product catalogue » Gearboxes » Cylindrical horizontal gearboxes » Two-stage gearboxes - 1Ts2U-100, 1Ts2U-125, 1Ts2U-160, 1Ts2U-200, 1Ts2U-250

Two-stage gearboxes - 1Ts2U-100, 1Ts2U-125, 1Ts2U-160, 1Ts2U-200, 1Ts2U-250

from 35000 ₽

| Number of steps |

Two-stage |

|---|---|

| Axis arrangement |

Parallel |

Further information on gearbox dimensions, shafts, gear ratios, etc. can be found in the catalogue.

Description

Assignment

Cylindrical two-stage horizontal gearboxes of general machine-building application of sizes 1Ts2U-100, 1Ts2U-125, 1Ts2U-200, 1Ts2U-250. are designed to change torques and speeds.

Application conditions of cylindrical gearboxes 1Ts2U-100, 1Ts2U-125, 1Ts2U-160, 1Ts2U-200, 1Ts2U-250:

- constant and variable load, single direction and reversible;

- working for long periods of time or with intermittent stops;

- rotation of the shafts in any direction;

- the input shaft speed must not exceed 1800 rpm;

- ambient temperature from minus 40C to plus 50C;

- atmosphere of types I and II according to GOST 15150-69 at air dustiness not more than 10 mg / cubic metre;

- climatic versions U, T for placement categories 1...3 and climatic versions UHL and O for placement categories 4 according to GOST 15150-69

Specifications

| Parameters | Size 1Ts2U | ||||||

| 100 | 125 | 160 | 200 | 250 | |||

| Nominal gear ratios | 8; 10; 12,5; 16; 20; 25; 31,5; 40 | ||||||

| Rated torque at output shaft during continuous operation with constant load, Nm | continuous (H) SP=100% | 315 | 630 | 1250 | 2500 | 5000 | |

| Rated output torque at the output shaft during repeated-short-time operation, Nm | heavy (T) SP=40% | 315 | 630 | 1600 | 3150 | 6300 | |

| medium (C) SP=25% | 2000 | 4000 | 8000 | ||||

| light (L)

SP=15% |

2500 | 5000 | 10000 | ||||

| Permissible radial cantilever load applied at the centre of the shaft seating,

Н |

input | continuous (H) SP=100% | 500 | 750 | 1000 | 2240 | 3150 |

| heavy (T) SP=40% | 1150 | 2500 | 3550 | ||||

| medium (C) SP=25% | 1280 | 2800 | 4000 | ||||

| light (L)

SP=15% |

1450 | 3150 | 4500 | ||||

| output | continuous(H) SP=100% | 4500 | 6300 | 9000 | 12500 | 18000 | |

| heavy (T) SP=40% | 10000 | 14000 | 20000 | ||||

| medium (C) SP=25% | 11200 | 16000 | 22400 | ||||

| light (L)

SP=15% |

12500 | 18000 | 25000 | ||||

| efficiency, at least | 0,97 | ||||||

| Weight, kg | cast-iron | 37 | 55 | 95 | 170 | 310 | |

| aluminium-clad | 21 | 31,5 | 57 | - | - | ||

| Type | аw2 | aw1 | L | L1 | 1 | 11 | l2 | l3 | Н | H1 | A | A1 | d | B | B1 | h | |

| no more | Cast iron housing | Aluminium housing | |||||||||||||||

| Gearbox 1Ts2U-100 | 100 | 80 | 390 | 325 | 136 | 85 | 136 | 165 | 230 | 112 | 290 | 109 | 15 | 155 | 145 | - | 20±3 |

| Gearbox 1Ts2U-125 | 125 | 80 | 446 | 375 | 160 | 106 | 145 | 206 | 272 | 132 | 335 | 125 | 19 | 175 | 165 | - | 22±3 |

| Gearbox 1Ts2U-160 | 160 | 100 | 557 | 475 | 200 | 135 | 170 | 224 | 345 | 170 | 425 | 140 | 24 | 206 | 195 | 24±4 | 28±4 |

| Gearbox 1Ts2U-200 | 200 | 125 | 678 | 580 | 243 | 165 | 212 | 280 | 425 | 212 | 515 | 165 | 24 | 243 | 230 | 30±4 | - |

| Gearbox 1Ts2U-250 | 250 | 160 | 829 | 730 | 290 | 212 | 265 | 335 | 530 | 265 | 670 | 218 | 28 | 290 | 280 | 32±4 | - |

Dimensions and sizes

Dimensions of input and output shaft ends

(customised shaft ends are available).

| Type | Shaft | d | d1 | d3 | d4,

no more |

l | l1 | b | h | t |

| Gearbox 1Ts2U-100 | in | 20 | 18,2 | M12x1,25 | 40 | 50 | 36 | 4 | 4 | 2,5 |

| Gearbox 1Ts2U-125 | 20 | 18,2 | M12x1,25 | 40 | 50 | 36 | 4 | 4 | 2,5 | |

| Gearbox 1Ts2U-160 | 25 | 22,9 | M16x1,5 | 45 | 60 | 42 | 5 | 5 | 3,0 | |

| Gearbox 1Ts2U-200 | 30 | 27,1 | M20x1.5 | 50 | 80 | 58 | 5 | 5 | 3,0 | |

| Gearbox 1Ts2U-250 | 40 | 35,9 | M24x2,0 | 63 | 110 | 82 | 10 | 8 | 5,0 | |

| Gearbox 1Ts2U-100 | exits | 35 | 32,10 | M20x1.5 | 50 | 80 | 58 | 6 | 6 | 3,5 |

| Gearbox 1Ts2U-125 | 45 | 40,90 | M30x2,0 | 75 | 110 | 82 | 12 | 8 | 5,0 | |

| Gearbox 1Ts2U-160 | 55 | 50,90 | M36x3,0 | 88 | 110 | 82 | 14 | 9 | 5,5 | |

| Gearbox 1Ts2U-200 | 70 | 64,75 | M48x3,0 | 100 | 140 | 105 | 18 | 11 | 7,0 | |

| Gearbox 1Ts2U-250 | 90 | 83,50 | M64x4,0 | 130 | 170 | 130 | 22 | 14 | 9,0 |