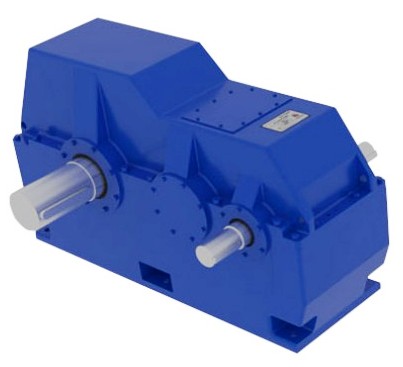

Two-stage gearboxes - Ts2N-450, Ts2N-500, Ts2N-630, Ts2N-710

from 750000 ₽ Original price was: 750000 ₽.650000 ₽Current price is: 650000 ₽.

| Axis arrangement |

Parallel |

|---|---|

| Number of steps |

Two-stage |

Further information on gearbox dimensions, shafts, gear ratios, etc. can be found in the catalogue.

IzhMSC manufactures a range of Ts2H type gearboxes with Novikov gearing, which is designed to provide increased endurance of active tooth surfaces, thus providing higher torque with relatively small gearbox dimensions.

Designation of Ts2H type gearboxes

Cylindrical two-stage gearboxes with Novikov gearing horizontal general machine-building application types Ts2N-450, Ts2N-500, Ts2N-630, Ts2N-710 are designed to increase torque and reduce speed.

- Gearbox housing made of cast iron castings grade CH20

- Reducer Ts2N-710 : castings body 0126.5.00.0.01 (weight 1620 kg), cover 0126.5.00.0.02 (weight 1140 kg)

- Gearbox Ts2H 630 : castings body 0125.5.00.0.01 a (weight 1100kg) and cover 0125 .5.00.0.02 B (weight 700kg)

- Gear shaft steel 40x Gost 4543-71 NV 260...290

- Gear Wheels: Casting 45L-II Gost 977-75 NV 179...207

Application conditions of Ts2H gearboxes

- constant and variable load, single direction and reversible;

- operation for long periods of time or with intermittent stops, shaft rotation in any direction;

- the input shaft speed must not exceed 1500 rpm;

- ambient temperature from minus 40°C to plus 50°C;

- increased dustiness, non-corrosive environment;

- climatic versions U, T (for placement category 1...4) according to GOST 15150-69.

Example of designation of gearbox Ts2N-630-25-12M(m12,z40)-U3:

spur gearbox (C), two-stage (2), with Novikov gears (H), axial distance of the low-speed stage 630 mm, nominal transmission ratio 25 assembly variant12, with the end of the low-speed shaft in the form of a toothed half coupling M(m12,z40) module12, number of teeth 40, climatic version U and placement category 3.

Assembly options:

| Type | TS2H-630 | TS2H-710 | ||

| Gear ratio | 8; 9; 10; 11,2; 14; 16; 18; 20; 22,4; 25; 28; 31,5; 35,5; 40; 45; 50 | |||

| Rated torque on output shaft, Nm | min | 71 000 | 100 000 | |

| max | 75 000 | 100 000 | ||

| Rated transmitted power, kW | min | 223 | 314 | |

| max | 697 | 982 | ||

| Permissible radial load applied to the centre of the shaft seating part, N | Output | min | 66 500 | 79 000 |

| max | 68 500 | 79 000 | ||

| Entry | min | 4 800 | 5 800 | |

| max | 10 000 | 13 000 | ||

| Weight, kg, not more | 3 675 | 4 920 | ||

Gearboxes are permitted to be subjected to short-term overloads of twice the rated overloads specified in the table and occurring during motor starting and stopping, provided that the number of output shaft cycles during these overloads does not exceed 5 - 10 4 during the entire service life of the gearbox.

The gearbox has a crankcase non-flowing lubrication system. It is recommended to fill the gearbox housing with the following oil grades: IRp-75, IRp-150 TU 38101451-78; ISp-65, ISp-110 TU 38101293-78, foreign oils: Mobilgear 627, Mobil D.T.E 27, Wiolan IT 150, MO 150 or other oils with kinematic viscosity in the range of 35-150 mm2 /s at temperature 50 °С.

| Size | i | awб | awт | L | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | ØD | ØD1 | ØD2 |

| Ts2H-450 gearbox | 8-50 | 280 | 450 | 1470 | 1060 | 530 | 260 | 170 | 300 | 500 | 650 | - | 480 | 35 | 80m6 | 160m6 |

| Ts2H-500 gearbox | 8-50 | 315 | 500 | 1650 | 1220 | 615 | 360 | 170 | 530 | 690 | - | 565 | 42 | 90m6 | 180m6 | |

| Ts2H-630 gearbox | 8-28 | 400 | 630 | 1960 | 1770 | 970 | 575 | 210 | 360 | 610 | 760 | 1920 | 660 | 52 | 110m6 | 220m6 |

| 31,5-50 | 170 | 570 | 80m6 | |||||||||||||

| Ts2H-710 gearbox | 8-28 | 450 | 710 | 2250 | 2010 | 1060 | 660 | 210 | 410 | 660 | 870 | 2160 | 742 | 125m6 | 250m6 | |

| 31,5-50 | 170 | 620 | 100m6 |

| Size | i | H | H1 | H2 | H3 | H4 | B | B1 | B2 | B3 | B4 |

| Reducer Ts2H-450 | 8-50 | 780 | 450 | 50 | 85 | 169 | 590 | 515 | 630 | 22 | 40 |

| Reducer Ts2H-500 | 8-50 | 1000 | 530 | 60 | 95 | 190 | 650 | 580 | 700 | 25 | 45 |

| Reducer Ts2N-630 | 8-28 | 1220 | 630 | 116 | 231 | 650 | 540 | 760 | 28 | 50 | |

| 31,5-50 | 85 | 22 | |||||||||

| Reducer Ts2N-710 | 8-28 | 1400 | 710 | 132 | 262 | 740 | 600 | 780 | 32 | 56 | |

| 31,5-50 | 106 | 28 |