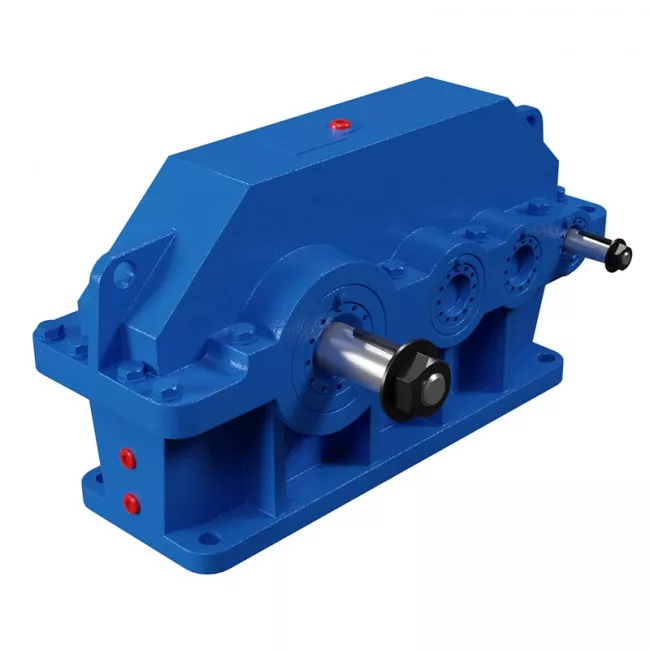

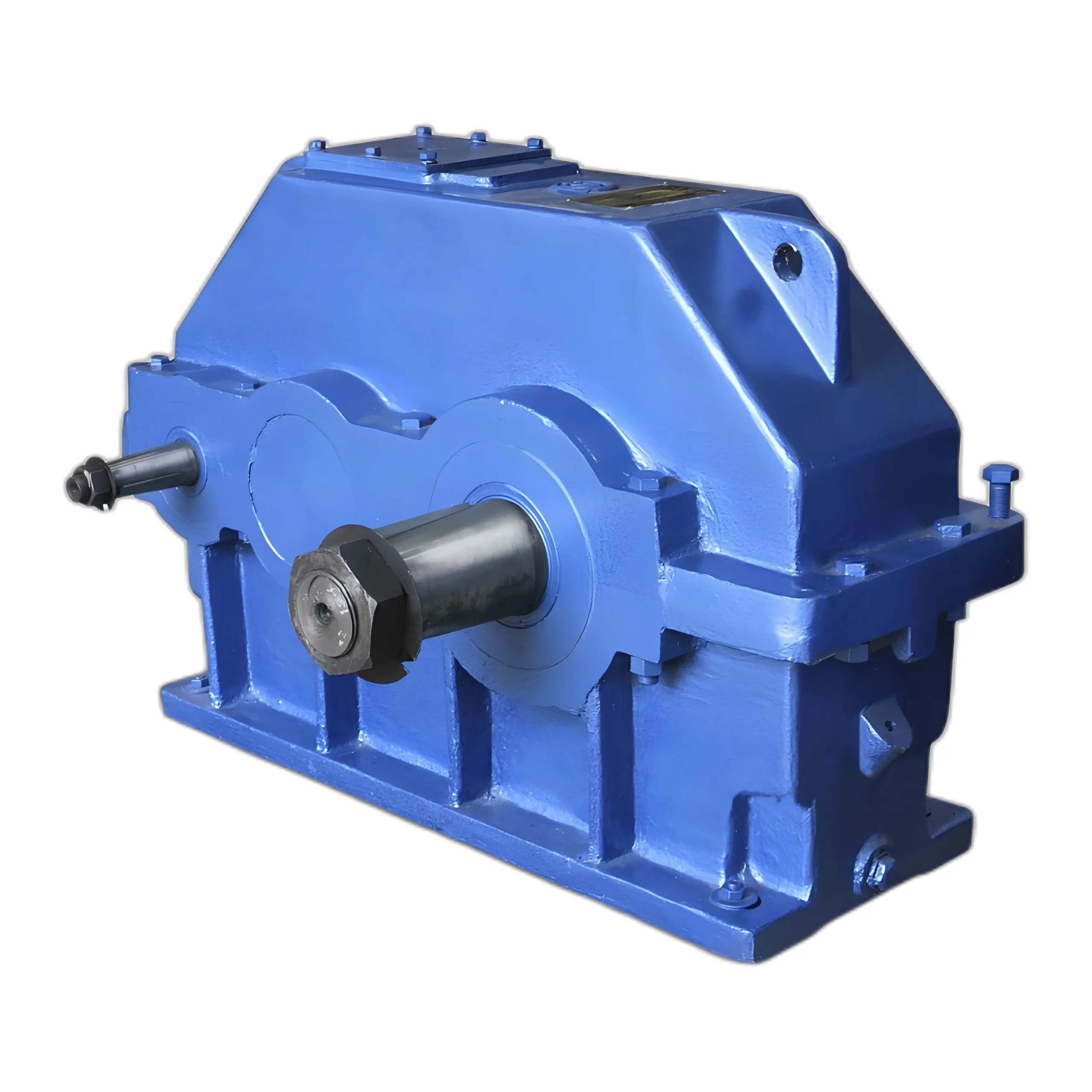

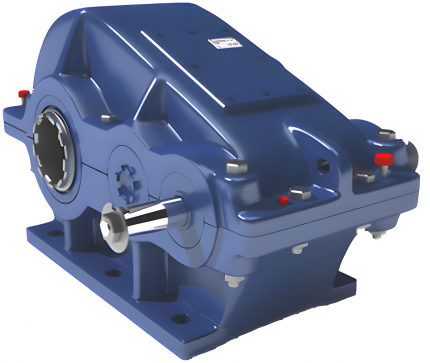

Three-stage gearboxes - 1Ts3U

from 36850 ₽

| Number of steps |

Three-stage |

|---|---|

| Axis arrangement |

Parallel |

Further information on gearbox dimensions, shafts, gear ratios, etc. can be found in the catalogue.

Assignment

1Ts3U gear reducers gear cylindrical three-stage narrow horizontal for general purpose are used to increase torques and reduce speeds. Gearboxes are used in macroclimatic regions with moderate climate (version U), dry and wet tropical climate (version T), placement categories 1, 2, 3, 4 (operation outdoors under a canopy, in closed rooms and rooms with regulated climate).

Conditions of application of cylindrical three-stage gearboxes 1Ts3U-160, 1TsZU-200, 1Ts3U-250:

- constant and variable load, single direction and reversible;

- working for long periods of time or with intermittent stops;

- rotation of the shafts in any direction;

- the input shaft speed must not exceed 1800 rpm;

- atmosphere of types I and II according to GOST 15150-69 at air dustiness not more than 10 mg / cubic metre;

- climatic versions U, T for placement category 1...3 and climatic versions UHL and O for placement category 4, and 1Ts3U gearboxes - 160 climatic version XL category 1...3 according to GOST 15150-69.

|

Parameter

|

Gearbox size

|

||

|

1TsZU-160 gearbox

|

1TsZU-200 gearbox

|

gearbox 1TsZU-250

|

|

| Rated output shaft torque N*m |

1000

|

2000

|

4000

|

| Nominal radial force, N: | |||

| at the input shaft |

500

|

1000

|

2000

|

| at the output shaft |

8000

|

11200

|

16000

|

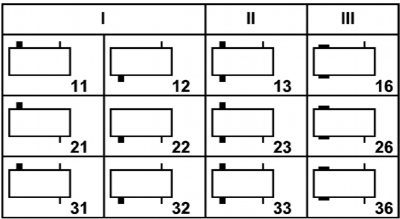

Assembly options:

І - with shaft ends under couplings,

as part of the gear coupling and with hollow output shaft of the 1Ts3U-250 gearbox

ІІ - with ends for couplings;

ІІІ - with hollow output shaft of 1Ts3U-200 gearboxes

Specifications:

| Parameter | Size 1Ts3U | ||||

| 160 | 200 | 250 | |||

Nominal gear ratios |

31,5; 40; 45; 50; 56; 63; 80; 100; 125; 160; 200 | 16; 20; 25; 31,5; 40; 45; 50; 56; 63; 80; 100; 125; 160; 200 | |||

| Rated torque at output shaft during continuous operation with constant load, Nm | continuous (H) SP=100% | 1250 | 2500 | 5000 | |

| Nominal torque at output shaft during repeated-short-time operation, Nm | heavy (T) SP=40% | 1600 | 3150 | 6300 | |

| medium (C) SP=25% | 2000 | 4000 | 8000 | ||

| light (L) SP=15% | 2500 | 5000 | 10000 | ||

| Permissible radial cantilever load applied at the centre of the shaft seating,

Н |

input | continuous (H) SP=100% | 630 | 1250 | 2240 |

| heavy (T) SP=40% | 710 | 1400 | 2500 | ||

| medium (C) SP=25% | 800 | 1600 | 2800 | ||

| light (L) SP=15% | 900 | 1800 | 3150 | ||

| output | continuous (H) SP=100% | 9000 | 12500 | 18000 | |

| heavy (T) SP=40% | 10000 | 14000 | 20000 | ||

| medium (C) SP=25% | 11200 | 16000 | 22400 | ||

| light (L) SP=15% | 12500 | 18000 | 25000 | ||

| EFFICIENCY | 0,96 | ||||

| Weight, kg | cast-iron | 110 | 190 | 335 | |

| aluminium-clad | 64 | - | - | ||

Notes on assemblies of 1Ts3U sizes:

- 160 with hollow output shaft is not manufactured;

- 200 with asymmetrical hollow output shaft is manufactured according to assembly variants 16, 26, 36;

- The 250 with a symmetrical hollow output shaft is manufactured according to assembly variants 11, 12, 21, 22, 31, 32, and with a cylindrical output shaft according to assembly variants 11, 12, 13, 21, 22, 23, 31, 32,33;

- 200, 250 with an output shaft in the form of a toothed half coupling are manufactured according to embodiments of assemblies 11, 12, 21, 22, 31, 32;

- 250 with output toothed shaft and parasitic gear - by 11, 22, 31, 32.

| Size

1TS3U |

160 | 200 | 250 | ||

| аw3 | 160 | 200 | 250 | ||

| аw2 | 100 | 125 | 160 | ||

| аw1 | 80 | 100 | 125 | ||

| L | no more | 630 | 775 | 950 | |

| L1 | 530 | 650 | 825 | ||

| l | 195 | 236 | 290 | ||

| l1 | 136 | 165 | 212 | ||

| l2 | 160 | 190 | 236 | ||

| l3 | 224 | 280 | 335 | ||

| H | no more | 345 | 425 | 530 | |

| H1 | 170 | 212 | 265 | ||

| A | 475 | 580 | 750 | ||

| A1 | 140 | 165 | 218 | ||

| B | 206 | 243 | 290 | ||

| B1 | 195 | 230 | 280 | ||

| d | 24 | 24 | 28 | ||

| h | cast-iron housing | 24±4 | 30±4 | 32±5 | |

| aluminium housing | 28-3+4 | - | - | ||

| Type | Shaft | d | d1 | d3 | d4,

no more |

l | l1 | b | h | t |

| 1Ts3U-160 gearbox | in | 20 | 18,2 | M12x1,25 | 40 | 50 | 36 | 4 | 4 | 2,5 |

| 1Ts3U-200 gearbox | 25 | 22,9 | M16x1,5 | 45 | 60 | 42 | 5 | 5 | 3,0 | |

| 1Ts3U-250 gearbox | 35 | 32,1 | M20x2,0 | 50 | 80 | 58 | 6 | 6 | 3,5 | |

| 1Ts3U-160 gearbox | exits | 55 | 50,90 | M36x3,0 | 88 | 110 | 82 | 14 | 9 | 5,5 |

| 1Ts3U-200 gearbox | 70 | 64,75 | M48x3,0 | 100 | 140 | 105 | 18 | 11 | 7,0 | |

| 1Ts3U-250 gearbox | 90 | 83,50 | M64x4,0 | 130 | 170 | 130 | 22 | 14 | 9,0 |